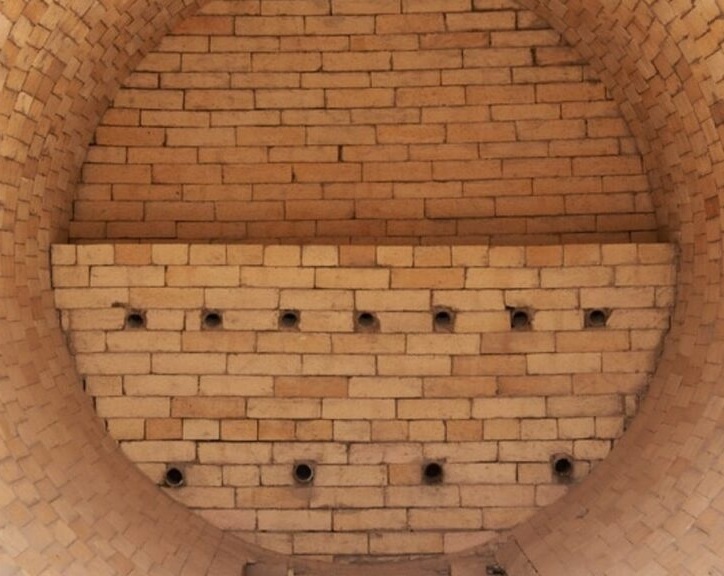

Comprehensive Support for Optimized Refractory Performance and Extended Lining Life

- Identification and diagnosis of refractory-related issues

- Pre-shutdown inspections and condition surveys

- Preparation of feasibility reports and detailed scope of work

- Engineering design and selection of suitable refractory materials

- Procurement management, including purchasing, quality control, and storage

- On-site testing, inspection, and technical supervision

- Oversight and coordination of contractors

- Installation, curing, and controlled drying processes

- Health and safety compliance with complete as-built documentation